In the corner of a testing laboratory in Singapore, a Haskel pump cycles rhythmically, barely audible above industrial machinery. To the untrained eye, this device appears almost primitive—a collection of pistons, seals, and chambers that could have been conceived decades ago. Yet this pneumatic liquid pump, driven by compressed air, routinely generates pressures exceeding 100,000 pounds per square inch, a force that would crush a human body in milliseconds.

The Haskel pump’s deceptive simplicity masks a profound truth about modern manufacturing: the most critical systems are often the most overlooked. These air-driven workhorses operate in testing facilities, research laboratories, and industrial plants across the globe, performing the essential but invisible work of pressurising, testing, and validating the components that keep our technological civilisation functioning.

The Quiet Revolution in Industrial Testing

The global hydraulic pump market, valued at USD 10.0 billion in 2024, is expected to reach USD 14.7 billion by 2033, exhibiting a growth rate of 4.33% annually. Singapore’s position in this market tells a compelling story. The Singapore pumps market is projected to grow at a CAGR of 5.9% during the forecast period, driven by rapid industrialisation, significant infrastructure investments, and growing automation demands.

These statistics reveal more than market trends—they expose the fundamental dependency of modern industry on pressure systems that most people never see or consider.

The Mechanical Honesty of Pneumatic Power

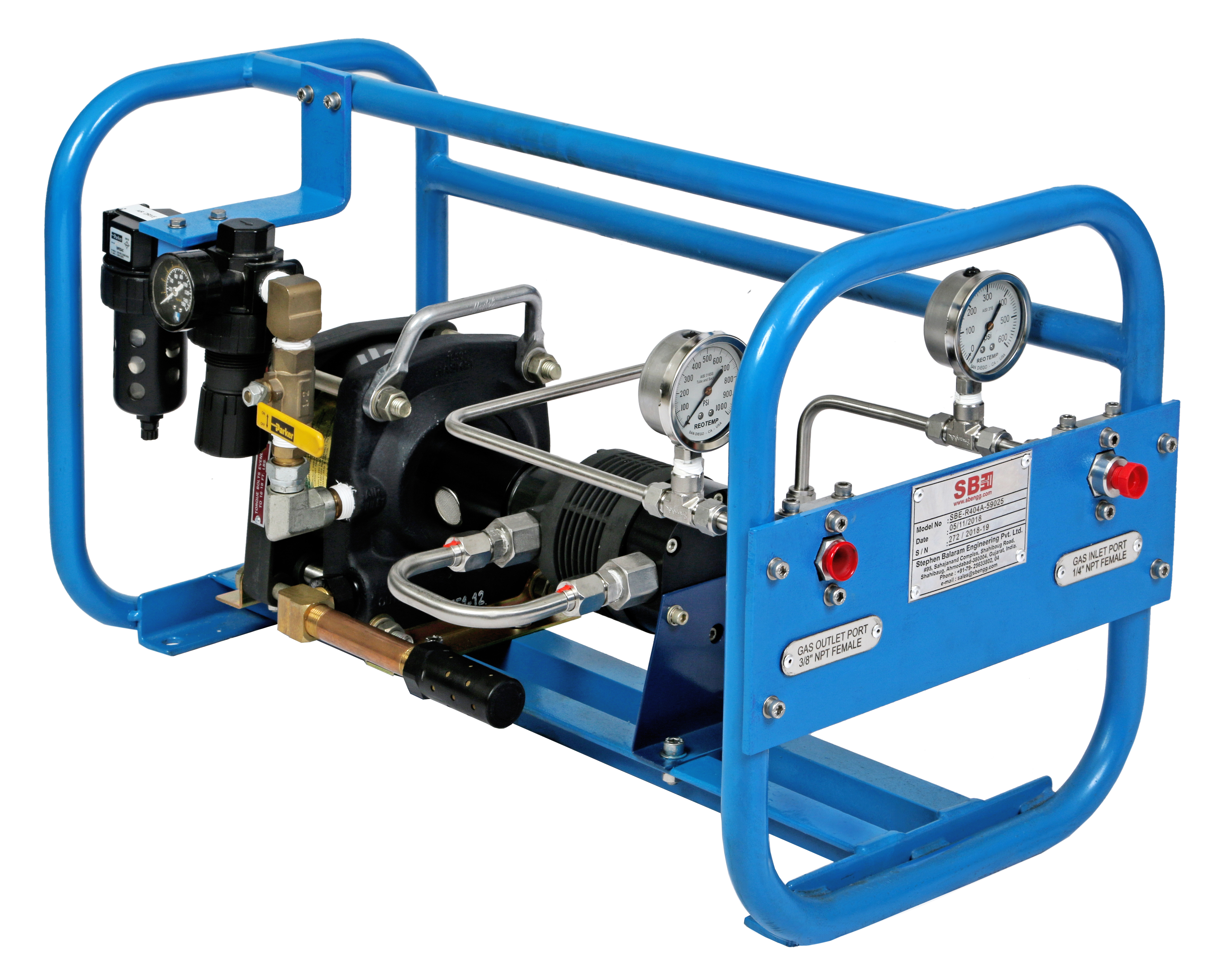

What makes a Haskel pump remarkable is its deliberate simplicity. Unlike electrically-driven systems, these pneumatic liquid pumps operate on a differential piston principle that borders on the elegant. Compressed air drives a larger piston, which drives a smaller hydraulic piston, amplifying pressure through mechanical advantage.

This design philosophy reflects industrial honesty that has become increasingly rare. There are no sensors to fail, no software to corrupt, no electrical components to short-circuit. The pump simply converts energy, repeatedly and reliably.

Key Technical Advantages:

-

Automatic pressure regulation through mechanical feedback systems

-

Infinite pressure holding capability without continuous energy consumption

-

Explosion-proof operation in hazardous environments

The Geography of Industrial Pressure

The Asia Pacific hydraulic pumps market, valued at USD 4.9 billion in 2024, reflects the region’s manufacturing dominance. Singapore, despite its small size, has positioned itself strategically by focusing on high-precision industrial components rather than mass production.

Singapore’s manufacturing sector has seen remarkable growth, ranking as the 5th largest machine producer in the Asia Tri-Region. This achievement becomes more significant considering the island nation’s space constraints and deliberate focus on precision engineering components, exactly where Haskel pumps excel.

The Invisible Infrastructure of Quality

In hydrostatic testing facilities across Singapore’s industrial parks, Haskel pumps perform critical validation functions:

Testing Applications:

-

Automotive components – brake lines, fuel systems, hydraulic parts

-

Aerospace parts – pressure vessels, fuel tanks, hydraulic systems

-

Industrial equipment – pipes, valves, pressure vessels

-

Safety-critical components – medical devices, nuclear equipment

The testing process itself is methodical and unforgiving. A component is sealed, connected to the pump, and subjected to pressures far exceeding its intended operating range. This process, repeated thousands of times daily worldwide, represents one of the most confrontations between engineering theory and physical reality.

The Economics of Pneumatic Efficiency

The financial logic of Haskel pumps becomes clear when examining their operational characteristics. Unlike electrical systems that consume power continuously, these pneumatic pumps draw energy only during active pumping. Once the target pressure is reached, the pump automatically stalls, maintaining pressure indefinitely without additional energy input.

This characteristic represents a fundamental efficiency advantage in testing applications. While electrically-driven systems require constant energy to maintain pressure, a Haskel pump can maintain 50,000 psi for hours using compressed air already available in most industrial facilities.

The Human Element in Industrial Systems

What strikes observers about Haskel pump operations is the human scale of the technology:

Operational Advantages:

-

Basic mechanical knowledge sufficient for operation and maintenance

-

No proprietary software systems to master

-

Standard tools adequate for repairs and servicing

-

Tactile feedback through air pressure changes for diagnostics

-

Audible operation allowing problem identification through sound

This accessibility stands in stark contrast to the increasing complexity of modern industrial systems. While Industry 4.0 promises connected, intelligent machinery, the fundamental work of generating and controlling pressure remains refreshingly mechanical.

The Future of Pressure Generation

As Singapore’s manufacturing sector evolves towards higher precision and automation, pneumatic pumps become increasingly significant. The global hydraulic pump market’s growth—from USD 10.0 billion in 2024 to USD 14.7 billion by 2033—suggests fundamental pressure generation needs remain constant despite technological advances.

Emerging Applications:

-

Hydrogen fuel cell testing requiring ultra-high pressures

-

Advanced materials validation for aerospace applications

-

Precision manufacturing of micro-components

-

Renewable energy component testing for wind and solar systems

-

Medical device validation under extreme pressure conditions

Driving Factors:

-

New materials development requiring sophisticated testing regimes

-

Component miniaturisation demands precise pressure control

-

Increasing performance demands across all industrial sectors

-

Safety regulations requiring more rigorous validation protocols

The Persistence of Mechanical Truth

In an industrial landscape increasingly dominated by digital systems, pneumatic pumps represent something profound about manufacturing’s fundamental nature:

Mechanical Advantages:

-

Unchanging physical laws – Force equals pressure times area

-

Energy conservation principles – Energy transformed, not created

-

Mechanical reliability vs. electronic fragility

-

Cyber-attack immunity – No digital vulnerabilities

-

Supply chain independence – Simple, replaceable components

These mechanical truths, embedded in every Haskel pump design, serve as a counterpoint to the complexity of modern industrial systems. In a world where software failures shut down production lines and cyber-attacks cripple infrastructure, pneumatic power offers a different model of industrial organisation.

The Haskel pump continues to operate, cycle after cycle, test after test, converting compressed air into extreme pressures that validate the integrity of our manufactured world, proving that sometimes the most sophisticated solution is also the simplest.